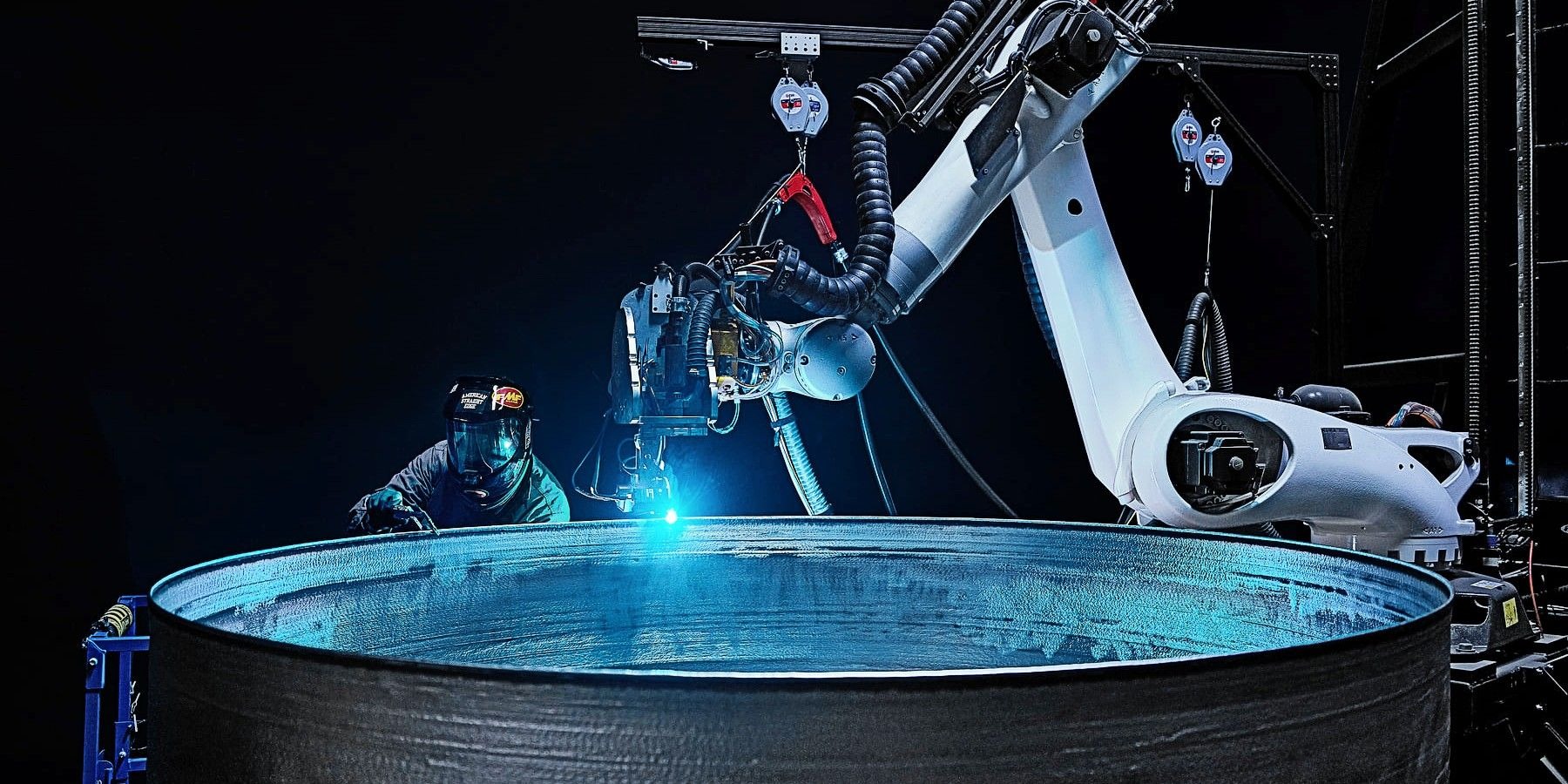

In our everyday lives, a 3D printer is a machine that can build objects by adding material layer by layer. It is used to make everything from toys to car parts and even houses. It is a new and exciting way to build things, and now, this technology is going to space. The future of space exploration depends on our ability to not just travel to other worlds but to live there, and 3D printing is a key technology that will make this possible.

Imagine an astronaut on a long trip to Mars who needs a new tool or a spare part for a broken machine. It would be impossible to send it from Earth. But with a 3D printer in space, the astronaut could simply print a new part on demand. This ability to build things in space is a game-changer. It will save a huge amount of money and make missions much safer and more self-sufficient. In this article, we will take a deep dive into the story of 3D printing in space, from its first uses on the International Space Station to its future role in building cities on the Moon and Mars.

What Is 3D Printing in Space? A New Way to Build

3D printing, also known as additive manufacturing, is a process where a machine builds a three-dimensional object from a digital file. It does this by adding material layer by layer until the object is complete. On Earth, this is a very common technology, but in space, it is a completely different story. The lack of gravity, the vacuum of space, and the need for new materials all create new challenges.

The biggest advantage of 3D printing in space is that it allows us to build what we need, when we need it. This is a huge benefit for long-term missions to the Moon and Mars, where it would take a long time and a lot of money to send a resupply mission from Earth. With a 3D printer, astronauts could have a cosmic factory right on their spaceship or in their habitat.

The First Steps: 3D Printing on the International Space Station

The story of 3D printing in space began on the International Space Station (ISS). In 2014, NASA and a company called Made In Space sent the first 3D printer to the ISS. The goal was to find out if 3D printing could be done in zero gravity.

The first object that was ever 3D printed in space was a faceplate for the printer itself. This proved that a 3D printer could work in zero gravity. In 2014, astronaut Barry “Butch” Wilmore installed the printer, and ground controllers sent the command to print the first object. The first parts were then sent back to Earth to be studied, and the results showed that the parts were even stronger in some ways than the ones that were printed on Earth.

The success of the first printer led to more advanced printers being sent to the ISS. Astronauts have since used these printers to make new tools and parts for the station. One of the most famous things that was printed was a plastic ratchet wrench, which showed that astronauts could make a tool they needed without having to wait for a resupply mission from Earth. The ability to make tools and parts on demand is a game-changer for space exploration.

The Next Frontier: Building on the Moon and Mars

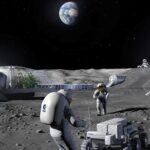

While 3D printing on the ISS is a huge step forward, the real power of this technology will be seen on the Moon and Mars. On these other worlds, we cannot just rely on resupply missions from Earth. We will have to use the resources that are already there to build our homes and our cities.

Building with Local Soil

The Moon and Mars are both covered in a layer of fine dust and rocks called regolith. This regolith is the perfect material for 3D printing. The plan is to send a robot to the Moon or Mars with a 3D printer. The robot would then use the local soil as its building material. It would use a powerful laser or a solar concentrator to heat up the regolith to a very high temperature, and it would then print habitats, landing pads, and roads directly on the surface.

Scientists have already been able to successfully 3D print structures from a simulant of lunar regolith in laboratories on Earth. These prototypes show that we could build strong, durable structures on the Moon without having to bring any building materials from Earth.

Robots and 3D Printing

The plan is to use robots to do all the heavy and dangerous work of building the first base on the Moon or Mars. A robot could land on the planet with a 3D printer and begin building the base before the first humans even arrive. This would be a great way to use the natural resources of the planet to protect the people inside. The robots would be able to build structures that are covered with a thick layer of regolith to protect the people inside from the deadly radiation and from micrometeoroid impacts.

The Benefits: Why 3D Printing Is So Important for Space

3D printing in space has a huge number of benefits that will be crucial for the future of space exploration.

- Less to Launch: The biggest benefit is that it saves a huge amount of money and weight. It costs a lot of money to launch every single thing from Earth. By using a 3D printer in space to make tools, parts, and even entire habitats from the local resources, we can save a huge amount of money and make missions more affordable.

- Fixing Things on the Fly: On a long mission to Mars, if a part of a machine breaks, it would be impossible to get a new one from Earth. With a 3D printer, astronauts can simply print a new part on demand. This makes a mission much safer and more self-sufficient.

- Using Local Resources: By using the resources that are already on the Moon and Mars, we can make our missions much more sustainable. The regolith on these planets is a huge and free source of building material. We can also use 3D printing to create tools and parts from recycled materials, like old spacecraft parts. This would reduce the amount of waste that we create in space.

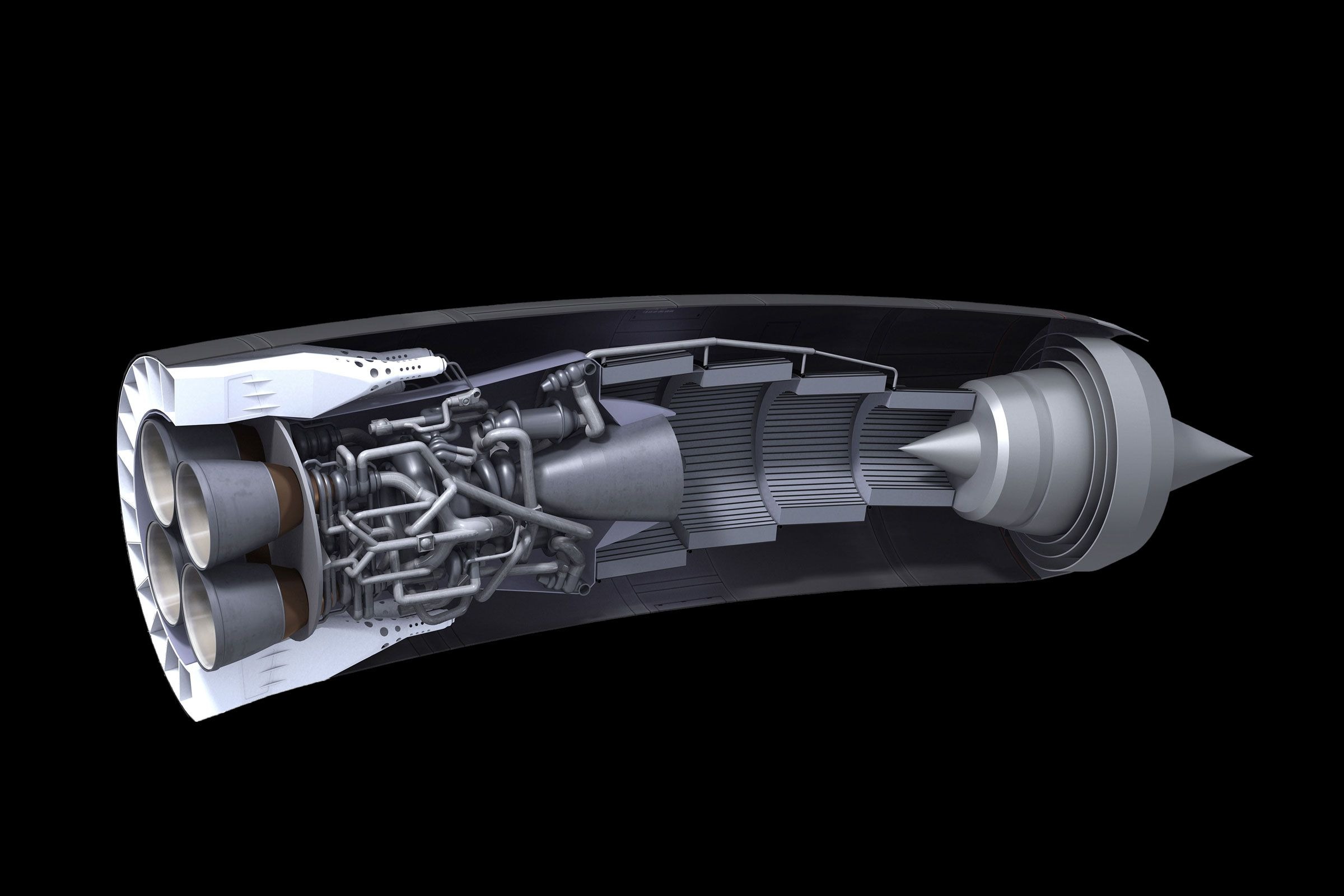

- Creating Complex Designs: 3D printing allows engineers to create complex shapes that would be impossible to make with traditional methods. This allows for new and innovative designs for rocket engines, satellite parts, and even habitats that are more efficient and more durable.

The Challenges: The Problems We Need to Solve

While 3D printing in space has a lot of promise, it also has some challenges that we need to solve.

- Working in Zero Gravity: On Earth, gravity helps to hold each layer of material in place. In zero gravity, a printer has to be able to hold the material in place without gravity’s help. This requires special materials and special designs for the printers.

- Working with Regolith: The regolith on the Moon and Mars is a very fine, dusty, and abrasive material. It can get into the printer’s delicate parts and cause them to break. We need to design a printer that can work in this dusty environment.

- Power and Automation: A 3D printer needs a lot of power to run, and it needs to be able to work on its own, without a human to help it. This is a very important challenge for a future mission to the Moon and Mars, where a robot will have to do all the building before the first humans arrive.

Conclusion

3D printing in space is a revolutionary technology that has the potential to completely change the way we do space exploration. It has already been used to make tools and parts on the International Space Station, and in the future, it will be used to build our first homes on the Moon and Mars from the local soil. The benefits of 3D printing in space, from saving money to making missions safer, are immense. While there are still some challenges that we need to solve, the promise of this technology is a testament to our ingenuity. It is a new way to build, and it is a key technology for a future where humanity will be a space-faring species.